The Cost of Cheap: Outsourcing and the Global Fashion Industry

Wearing an outfit consisting of items made across the world is not just unsurprising: it is the norm. But why is a global wardrobe so commonplace, and what does it mean, for people and planet?

‘Outsourcing’. ‘Offshoring’. Two stalwarts of contemporary parlance, these banal terms belie a ghoulish reality. Both processes - despite their quasi-euphemistic, sanitised ‘bleh’-ness - encapsulate the transformations to economies and the lives of millions that have occurred over the last few decades. The fashion industry is a powerful distillation of this global reorganisation. You need only look at the labels in your wardrobe, or on the rails in your local department store, to see just how international clothing production is. Of course, the “Made in Vietnam” tag on a pair of new Levi’s is misleading in itself. Before the jeans were finally assembled there, it is likely that the metal for the rivets, and the cotton for the fabric, were mined, refined, machined, harvested, ginned, carded, combed, spun, washed, washed again, dyed, distressed, and cut by a legion of workers, employed by a web of companies, across a multitude of countries. Before your jeans have walked a single step outside the shop, they have likely already travelled some 65,000km (that’s one and a half times around the world)1!

I photographed these labels from a single rail of menswear in a charity shop in South London - I imagine the selection is fairly representative of the British wardrobe. I encourage you to look at your own wardrobe and think for a moment about the globally entangled industries that make up our everyday lives.

Outsourcing refers to the subcontracting of some part of the production process, whilst offshoring is simply the transfer of labour from one country to another. The ultimate reason why a textile company or fashion house decides to outsource, or offshore, part of its production process is to reduce costs and increase profit. Whilst business orthodoxy might argue ‘no! It’s about labour costs’ or ‘that’s too simplistic, sometimes companies need to spread risk and increase efficiency and take advantage of specialised labour and [insert corporate jargon ad infinitum]…’, the corollary is almost always because this will reduce costs. (Not always! Story mfg outsources their dyeing process to India, in order to take advantage of the skills and experience of talented, well-compensated artisans. But the dealings of a small brand with a foundational dedication to transparency and sustainability occupy a separate ball game entirely to the behemoths of the clothing industry).

Lowering costs allows the business - as well as the coffers of its owners - to grow. This doesn’t inherently jeopardise workers, or lead to exploitation in every case. Indeed, some argue that the clothing industry’s globalising push has had an emancipatory effect on women. The disproportionately-female workforce of clothing production has given financial agency (or at least an approximation of that) to many women, but patriarchal systems remain in place, and conditions are often very exploitative (more on this in a few weeks!).

Along a similar line of reasoning, outsourcing and offshoring can be seen as having bolstered developing economies, providing much needed foreign income. A fairly valid point. Through fiscally-tinted lenses, the ostensible ‘creation’ of textile industries, and consequent economic growth across the developing world have been positive. However, if orthodox economists and politicians appropriately valued non-economic impacts, the socioeconomic inequalities and ecological destruction that these industries produce in countries such as Vietnam, or Bangladesh, somewhat weaken the argument. This argument also ignores the fact that much of the economic value created in manufacturing hubs in the Global South is then drained out by foreign parent companies, which relocated in the first place to widen profit margins.

Global clothing production doesn’t deserve a saviour complex: not for its ‘emancipation’ of women, nor its contributions to economies. In many cases, far from boosting the health of economies, aggressive outsourcing and offshoring can foster dependence, exposing nations to volatile prices. This dependence is not just caused by governments seeking national (and sometimes personal) enrichment, but also a coterie of institutions and ‘common-sense’ economic orthodoxy, spreading the gospel of neoliberalism.

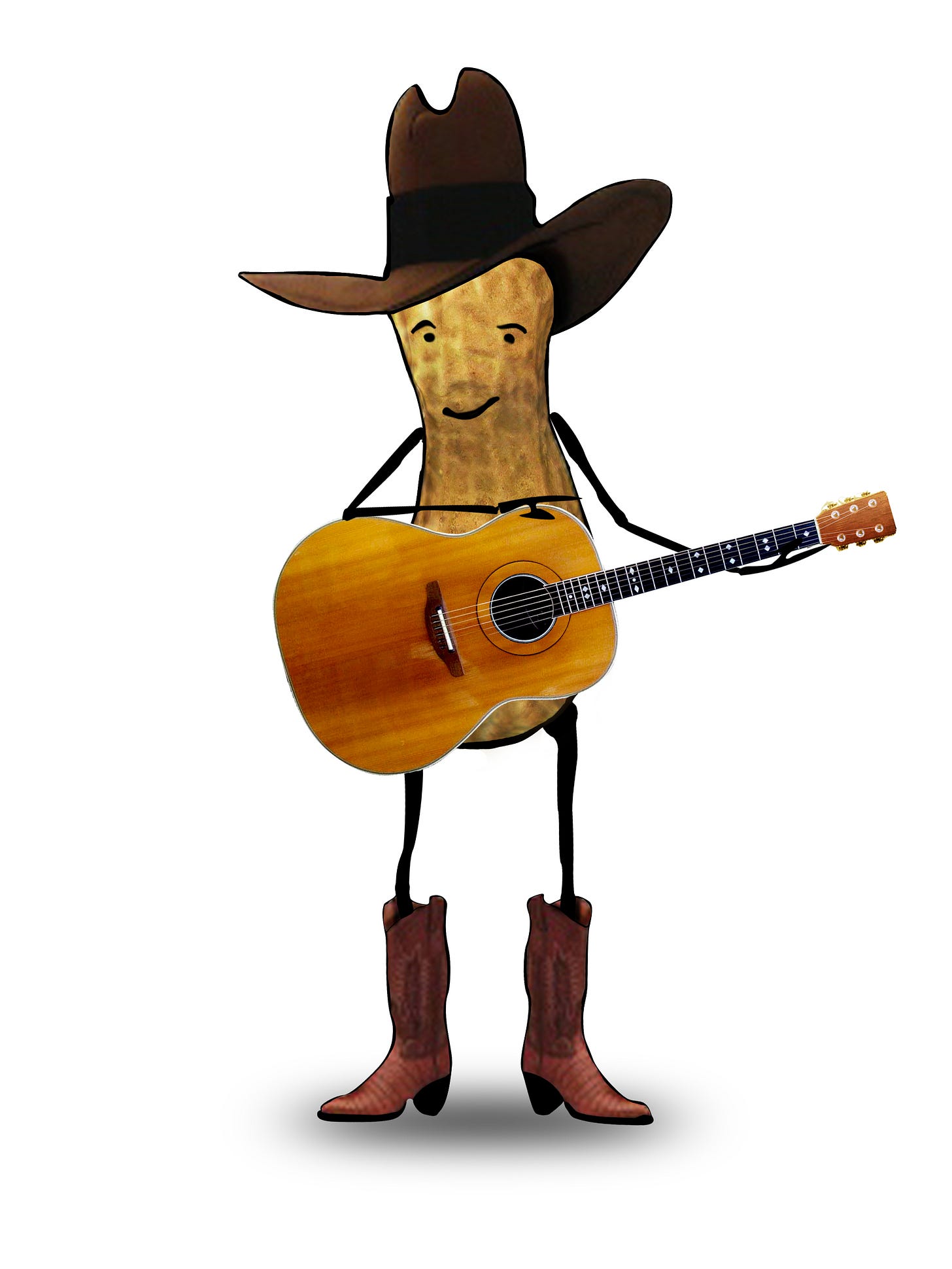

To explore this phenomenon, I will fall back on one timeless (it's actually terribly dated) fever dream of a GCSE geography case study: ‘The Luckiest Nut in the World’. The film is narrated by a stetson-donning, cowboy boot-sporting, guitar-wielding peanut, with a terrible attempt at a Southern drawl. In the film, we see how this true American patriot lives a life of nutty privilege, propped up by protectionist tariffs, government subsidies, and import restrictions. Unlike this lucky nut, the documentary(?) features nuts from across Africa who have fallen on harder times. Institutions such as the World Bank, and the World Trade Organisation have pushed an agenda of extreme liberalisation for decades; this means less tariffs, less red tape, lower taxes, and the celebration of a frictionless ‘free’ market. For large companies seeking to buy commodities like cotton (or peanuts), or outsource their production, this liberalisation is a boon to profit margins.

In the case of Senegal, their development was facilitated by conditional loans from the World Bank, the attached strings of which demanded the growth of peanut exports to pay back loans (and interest). As Senegal’s economy pivoted away from food production to cash-crops like peanuts, the country became increasingly dependent on cash raised from these exports (because it had to use this cash to import food for its people). Suddenly, as many African countries upped peanut production on the advice of the World Bank, supply became bloated, prices plummeted, and economies nosedived. Privatisation and cuts to public spending ensued. Senegal currently spends more on debt repayment than healthcare and education combined.

Whilst clothes aren’t generally made of peanuts, the lessons of the unlucky nuts are paralleled in textile production: in some developing nations, up to 7% of employees are involved in cotton production alone. Price shocks jeopardise employment for workers, as well as the health of textile-dependent economies at large, which can then affect the provision of public services and infrastructure. Worse, textile production has to account for changing tastes, and ephemeral trends: nuts are never out of fashion. As a result, many textile producers and garment makers in the developing world are in thrall to the global market, dictated by the whims of global conglomerates, as well as the artificially-enhanced trend cycles and tastes of consumers. The effects of this dependence can be devastating in cotton-producing regions like Uzbekistan, and this became abundantly clear during COVID: when the housebound Western world’s need for new clothes and trends temporarily paused, large fashion houses left their Global South suppliers in the lurch.

The low cost of production sniffed out by the clothing industry isn’t just a factor of low wages and purchasing power, but also a result of regulatory absences in the developing world. The ‘race to the bottom’ undertaken by governments to create ‘attractive’ opportunities for foreign investment has incentivised de-regulation - or at least, an inertia against regulation - of textile industries. Compounded by the influence of the aforementioned neoliberal missionaries of the World Bank, textile industries often grow rapidly without the sufficient leadership and practical knowledge to ensure that they develop safely, let alone sustainably.

The fallout for workers is literally deadly. In the machine-intensive cotton industry, the respiratory illness byssinosis is widespread. In Ethiopia, researchers have found that 16% of workers in the garment industry suffer from byssinosis. In certain, dustier sections of cotton production, this proportion rises to a horrifying 43%. Similar figures have been identified in Nigeria and Zimbabwe, and one can only assume that this elevated incidence of byssinosis is commonplace across the developing world’s textile industries. The existence of these dangerous conditions is a result of industries forcing costs down: fair pay and decent working conditions are expensive, and are consequently anathema to the profit incentive.

So far, we have seen how the process of outsourcing, at least in its broadly neoliberal configuration, can cause serious downsides across the developing world. But what for the domestic economies, which the textile industry has vacated through outsourcing? In the UK, it is evident that the domestic textile industry has been hit hard over the last century. In a bid to survive, textile production in the UK has had to compete with the cheap labour and under-regulation found across the developing world.

One way to lower overheads has been to exploit migrant workers, many of whom are undocumented, and can consequently be paid a pittance. Exposed to harsh punishment, bullying, and strict surveillance in the name of streamlining production, these workers endure terrible conditions. By importing the poor labour standards of some developing economies to a supposedly developed economy in the UK, companies like JD Sports and Boohoo have managed to stay ‘competitive’. The awful conditions of the latter were exposed in Leicester in 2020, where journalists uncovered rife neglect of fire codes, COVID regulations, and found many workers earning barely £3 an hour.

As a result of mass-outsourcing, domestic textile producers have engaged in a similar ‘race to the bottom’ to stay competitive, resulting in foul violations of labour laws. There is a cruel irony that the victims of this exploitation are disproportionately migrant communities, with little recourse for assistance, and who may have come from countries with similarly exploitative garment industries.

One further issue remains, and is part of why ‘fixing’ the clothing industry seems so difficult. New garments - especially those produced by large fast fashion companies - are stitched together by a Gordian knot of different stakeholders and workers, making their social, economic, and environmental impacts (as well as their cost!) a near-unintelligible mess. With such opaque and convoluted supply chains, it is hard to evaluate the impact of fashion’s big players, and perhaps even harder to make these impacts less damaging.

In the corporate hellscape of ESG (the current watchword of commercial sustainability), the trend is towards data collection and measurement: companies seeking to improve their credentials - or simply pay lip service to sustainability - must first be able to ‘see’ themselves and their environmental footprint before they can take action. The proliferation of professional services and tools dedicated to allowing companies to quantify their impact captures the intricacies of international supply chains. It would be a gargantuan effort for LVMH, for example, to calculate the total emissions and waste generated not just by its own activities, but those of the myriad companies and factories it outsources production, manufacturing, transport, storage, and advertising to. This limits the ability of corporate ‘good guys’ to affect positive change. Simultaneously, the subcontracting process allows companies to outsource accountability, and responsibility, into an opaque supply chain - inscrutable, and thus unfixable.

Borne from a desire to ramp up production, lower costs, and increase profits, these convoluted and opaque supply chains are fundamental to allowing such travesties - from endemic byssinosis to illegally low wages, and from polluted rivers to child labour - to occur on an unexceptional basis. What I’m arguing is that the exploitative elements of outsourcing aren’t necessarily an anomaly, but happen because the most profitable system is one that embraces regulatory absences, corporate oversight (willing or unwilling), and irresponsible cost-cutting. There is no cabal of suited executives clamouring for their workers to suffer: outsourcing is simply good business. And as long as ‘good business’ is incentivised by profit-above-all-else, ignorant of social and environmental fallout, then ‘good-business-as-usual’ will continue to be the true cost of cheap.

1: ADEME 2022

Bibliography

Alemu, K., Kumie, A. and Davey, G., 2010. Byssinosis and other respiratory symptoms among factory workers in Akaki textile factory, Ethiopia. Ethiopian Journal of Health Development, 24(2).

Al-Rubeyi, 2018. Evidence of the Hand: thoughts on the cost of craft, the cost of sustainability, the cost of everything. Story mfg. Available at: https://www.storymfg.com/blogs/essays/evidence-of-the-hand-thoughts-on-the-cost-of-craft-the-cost-of-sustainability-the-cost-of-everything

Butler, S., 2019. Revealed: 'shocking' lack of regulation at Leicester garment factories. The Guardian. Available at: https://www.theguardian.com/uk-news/2020/aug/30/revealed-shocking-lack-of-regulation-at-leicester-garment-factories.

Butler, S. 2022. Activists to question Boohoo on living wage for Leicester garment workers. The Guardian. Available at: https://www.theguardian.com/business/2022/jun/17/activists-to-question-boohoo-on-living-wage-for-leicester-garment-workers

Davies, R., and Kelly, A., 2020. More than £1bn wiped off Boohoo value as it investigates Leicester factory. The Guardian. Available at: https://www.theguardian.com/business/2020/jul/06/boohoo-leicester-factory-conditions-covid-19

Frey, D.F., 2017. Economic growth, full employment and decent work: The means and ends in SDG 8. The International Journal of Human Rights, 21(8), pp.1164-1184.

International Labour Organisation, 2017. The Rana Plaza Accident and its aftermath. ILO. Available at: https://www.ilo.org/global/topics/geip/WCMS_614394/lang--en/index.htm

Kelly, A., 2020. 'National shame': MP sounds alarm over UK fast fashion factories. The Guardian. Available at: https://www.theguardian.com/global-development/2020/jan/23/national-shame-mp-sounds-alarm-over-uk-fast-fashion-factories.

Moen, B.E., Nyarubeli, I.P., Tungu, A.M., Ngowi, A.V., Kumie, A., Deressa, W. and Mamuya, S.H.D., 2020. The challenge of obtaining a decent work environment in Sub-Saharan Africa. In Africa and the Sustainable Development Goals (pp. 155-164). Springer, Cham.

Siddiqui, J. and Uddin, S., 2016. Human rights disasters, corporate accountability and the state: Lessons learned from Rana Plaza. Accounting, Auditing & Accountability Journal.

https://www.ellenmacarthurfoundation.org/fashion-and-the-circular-economy-deep-dive

https://emily-james.com/the-luckiest-nut-in-the-world/

ADEME, 2022. The Underside of my Look: What Impacts Do My Clothes and Shoes Have on the Planet? Agence de l'environnement et de la maîtrise de l'énergie. Available at: https://librairie.ademe.fr/cadic/1460/lrdml_maquette_33_bat_en_web.pdf